The problem... the mode switch has two shafts,

coupled between the front detent (1/4 inch shaft)

and the rear contacts (3/16 flat walled shaft). The

coupler is plastic and this one had become loose;

not gripping the contact shaft as it should.

This allowed the rear shaft to slide back with use

until it was clear of the coupler. I had a couple of

choices here to fix this. I could have taken the

switch apart and used epoxy to glue the shaft into

the coupler. I decided against this approach

because the coupler was so close to the

contacts... any epoxy on the contacts would ruin

the switch. Another reason is that once glued

together, the switch could never be disassembled

again. Also, the switch can be inserted 180

degrees off, and making that correct orientation

during assembly was a risk I did not want to take..

coupled between the front detent (1/4 inch shaft)

and the rear contacts (3/16 flat walled shaft). The

coupler is plastic and this one had become loose;

not gripping the contact shaft as it should.

This allowed the rear shaft to slide back with use

until it was clear of the coupler. I had a couple of

choices here to fix this. I could have taken the

switch apart and used epoxy to glue the shaft into

the coupler. I decided against this approach

because the coupler was so close to the

contacts... any epoxy on the contacts would ruin

the switch. Another reason is that once glued

together, the switch could never be disassembled

again. Also, the switch can be inserted 180

degrees off, and making that correct orientation

during assembly was a risk I did not want to take..

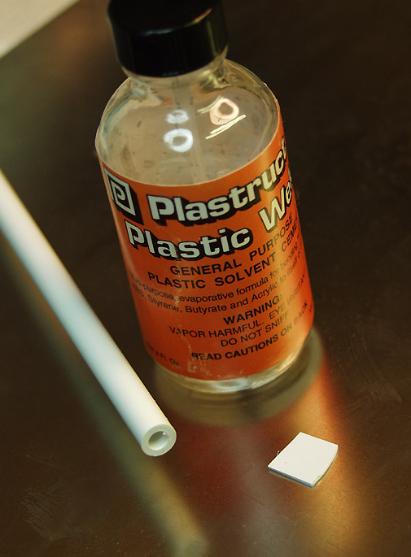

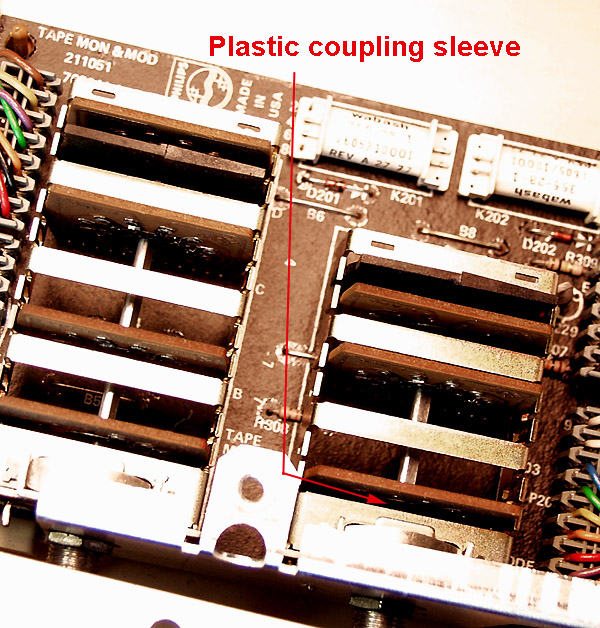

Instead, I chose to make a retainer for the back of the shaft, out of Styrene plastic. I used heavy walled plastic pipe

and a small section of sheet plastic. This was assembled to make a cap, which was worked to the precise length to

just clear the shaft. This was glued to the plastic shaft support at the rear of the switch. This keeps the shaft where it

should be and the switch is still serviceable should the need arrise...

and a small section of sheet plastic. This was assembled to make a cap, which was worked to the precise length to

just clear the shaft. This was glued to the plastic shaft support at the rear of the switch. This keeps the shaft where it

should be and the switch is still serviceable should the need arrise...

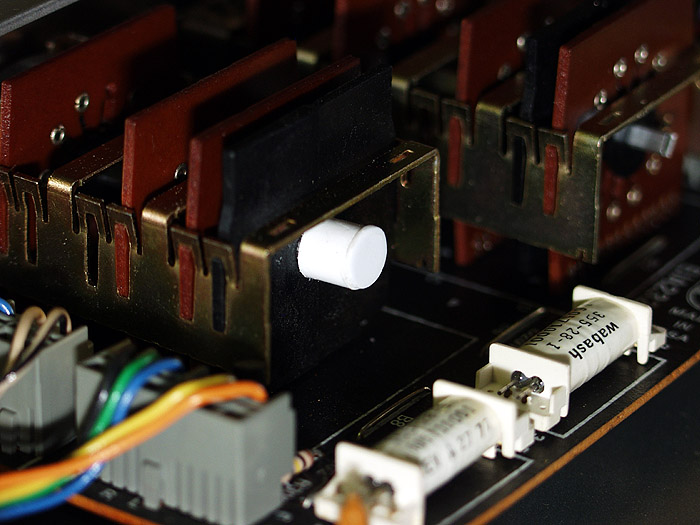

Problem Switch...

A loose shaft

coupler allowed the

rear shaft to slide

free from the forward

knob and shaft. You

can see the location

of the shaft coupler.

It sits right in front of

the first contact wafer.

A loose shaft

coupler allowed the

rear shaft to slide

free from the forward

knob and shaft. You

can see the location

of the shaft coupler.

It sits right in front of

the first contact wafer.