Taking Care Of Rust...

There are two ways I handle rust. One is to use electrolysis. This is very effective if you don't have to worry about

stripping paint, and there is only steel involved (no metals like stainless, copper, aluminium, etc...) This is my

preferred method as it does not attack the metal.

In this case, I had to strip the old zinc plate, so I opted to use a meriatic acid solution. All the chassis parts were

soaked for a shot time. This strips the plating and removes all the rust. Once this has been done you are ready to

re-plate the parts. However, if you want a really shiny surface, you will have to spend time polishing prior to plating.

What you start with, is pretty much what you end up with. I spent time polishing the surfaces that are easily visible.

Polishing is a time consuming process. I spent hours on this, and there are still plenty of blemishes showing through

the new plating. However, I spent enough time to ensure that the areas seen were smooth so the unit would present

well.

Also, I put several heavy layers of bright zinc on the chassis parts. This will give good protection even in harsh damp

areas and also allowed me to cover over and polish out some of the minor under-laying blemishes.

Plating Setup...

stripping paint, and there is only steel involved (no metals like stainless, copper, aluminium, etc...) This is my

preferred method as it does not attack the metal.

In this case, I had to strip the old zinc plate, so I opted to use a meriatic acid solution. All the chassis parts were

soaked for a shot time. This strips the plating and removes all the rust. Once this has been done you are ready to

re-plate the parts. However, if you want a really shiny surface, you will have to spend time polishing prior to plating.

What you start with, is pretty much what you end up with. I spent time polishing the surfaces that are easily visible.

Polishing is a time consuming process. I spent hours on this, and there are still plenty of blemishes showing through

the new plating. However, I spent enough time to ensure that the areas seen were smooth so the unit would present

well.

Also, I put several heavy layers of bright zinc on the chassis parts. This will give good protection even in harsh damp

areas and also allowed me to cover over and polish out some of the minor under-laying blemishes.

Plating Setup...

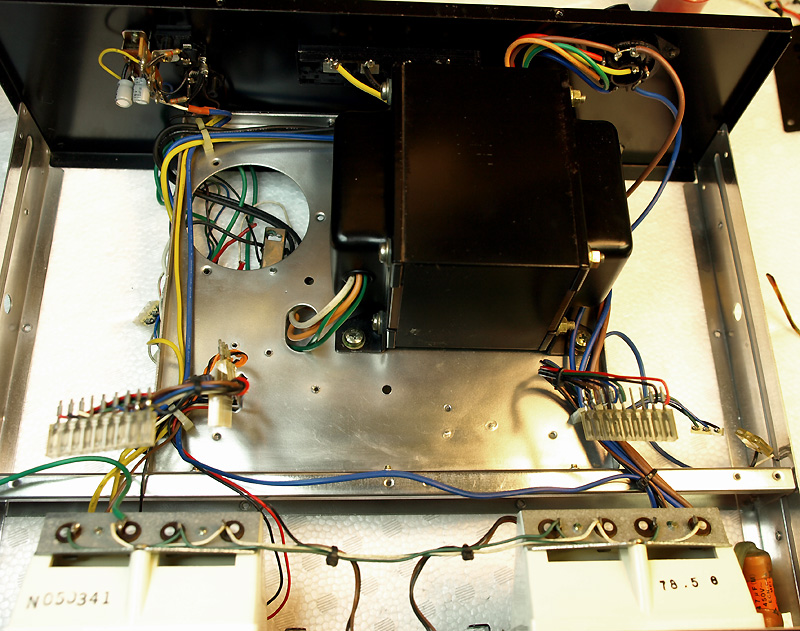

My set up consists of a holding tank for the part and electrolyte, DC power supply (6V - 12V), and an electrolyte

solution.

Plating current is relative to the area being plated, so a method for controlling this is needed. I use the same resistor

array I use as a dummy load for amplifier testing. These are 25W 2 ohm resistors. I can tap into any spot, which

allows me to adjust the load from 2 - 16 ohms, in 2 ohm steps. Here... I am using 6 ohms.

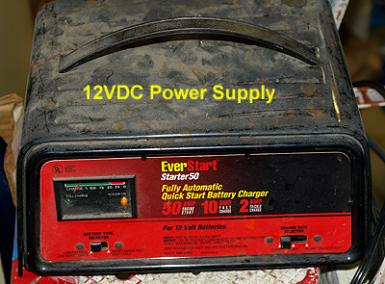

My power supply is a heavy duty battery charger with a selectable current limiter. I always set to the lowest (2 amp)

setting.

solution.

Plating current is relative to the area being plated, so a method for controlling this is needed. I use the same resistor

array I use as a dummy load for amplifier testing. These are 25W 2 ohm resistors. I can tap into any spot, which

allows me to adjust the load from 2 - 16 ohms, in 2 ohm steps. Here... I am using 6 ohms.

My power supply is a heavy duty battery charger with a selectable current limiter. I always set to the lowest (2 amp)

setting.

When the part is taken out of the solution, it is milky

white. This has to be polished to a shine. Again... I

polished the exposed part that is going to be seen,

to a high shine. I polished the under side (coved by

the power supply board) only enough to remove the

white coating and expose the bare zinc plate. Each

piece of the chassis is plated and polished in a

similar way.

white. This has to be polished to a shine. Again... I

polished the exposed part that is going to be seen,

to a high shine. I polished the under side (coved by

the power supply board) only enough to remove the

white coating and expose the bare zinc plate. Each

piece of the chassis is plated and polished in a

similar way.

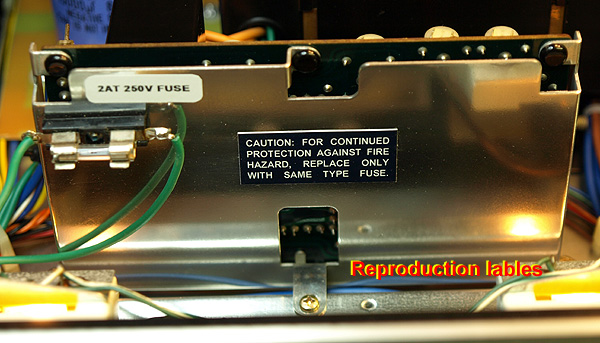

<- Before...

After ->

Completed Chassis