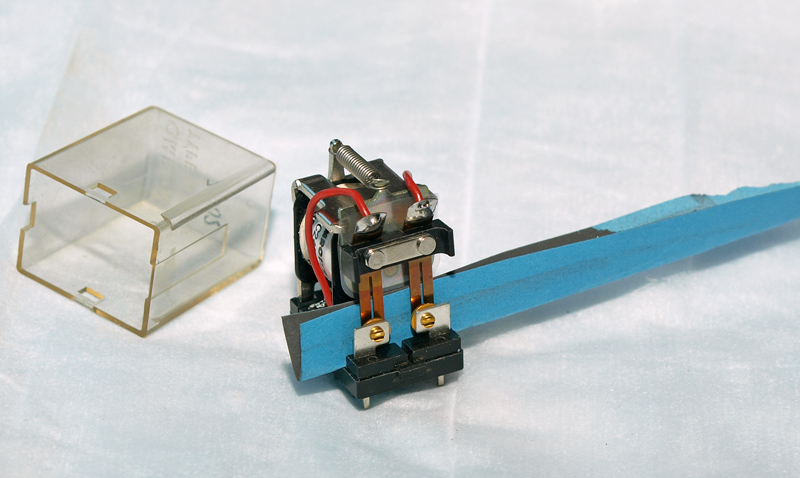

This is 1500 grit sand paper. It is very fine, but it is all that is needed to clean the carbon from the contacts. I fold

a strip in half length wise and place it between the contacts. Place light pressure on the contact arms to close

them and pull the paper through. Just one or two passes is all that is required to clean up the contacts.

a strip in half length wise and place it between the contacts. Place light pressure on the contact arms to close

them and pull the paper through. Just one or two passes is all that is required to clean up the contacts.

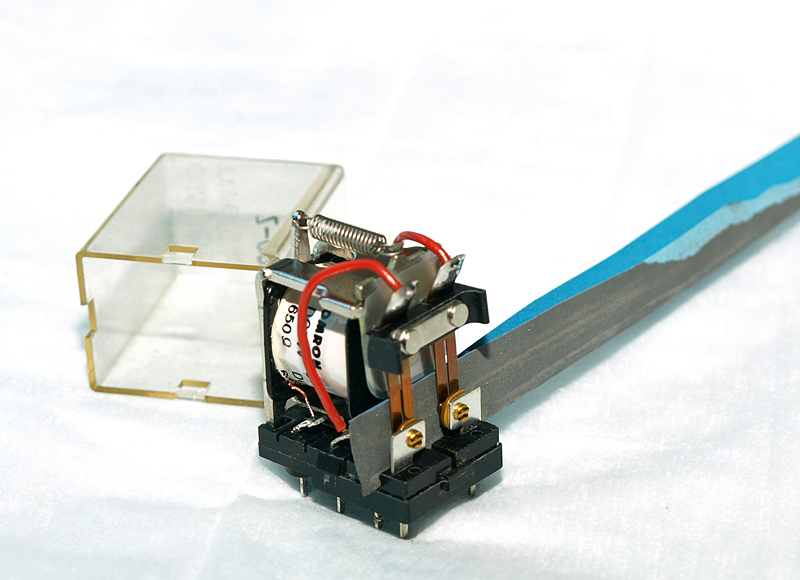

Now, reverse the fold on the same strip of sand paper, so that the paper backing is out. Make several passes

just as described above. This will polish the contact face to a mirror finish. A polished surface will resist carbon

buildup because it does not expose a low-resistance "edge" for arching (resistance breaks down along the

edges of imperfections on conductive surfaces).

just as described above. This will polish the contact face to a mirror finish. A polished surface will resist carbon

buildup because it does not expose a low-resistance "edge" for arching (resistance breaks down along the

edges of imperfections on conductive surfaces).

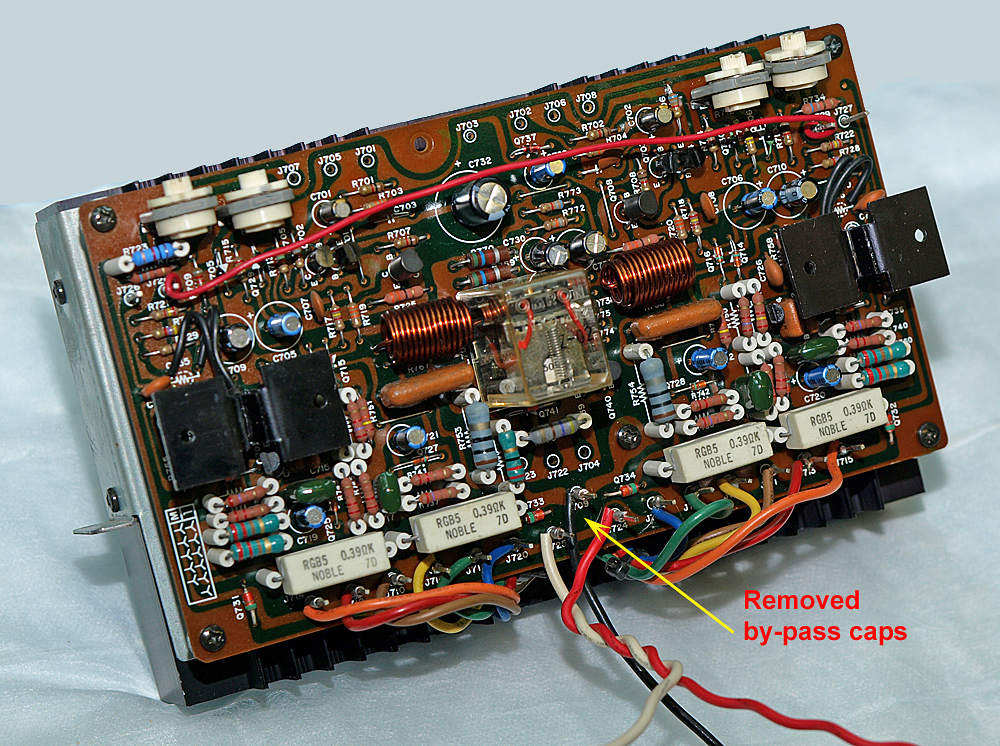

Here is the completed

board. You can see it

looks much less crowded

without the by-pass caps

board. You can see it

looks much less crowded

without the by-pass caps