Dilemma...

What do you do when you need a high quality 12,000uf capacitor that is 40mm x 100mm and can't find one?

Well, if you can find a 40mm diameter that is anywhere form 60-100mm you can make that work, but the 40mm diameter is

something you just got to have. You can change all the mounting hardware, and drill new mounting holes... sometimes (but I

hate drilling new holes into a vintage piece of equipment). Most often, there are limiting factors, such as space, specialized

clamps and hardware, or PCB layout that prohibits the use of anything except the proper diameter cap. This is the case with

the KA-9100...

The mounting clamps are a unique double capacitor bracket. Further, the rectifier board mounting positions are dependent on

the capacitors because the boards hang from the base of the capacitors. The clamp holds the whole thing in position. The

position of the boards are critical because the tolerances between the components and PCB hardware and the frame are

small.

You just have to have 40mm capacitors!!! I looked everywhere for 40mm x 12,000uf caps... nothing!!!

40mm is an old standard and not many caps are available in this diameter today. These days, you find 35mm as a common

standard size. So, the best I could find was 35mm x 70mm.

This next section describes what I did to make these work with the original clamps and hardware. It worked quite well, but

requires some specialized equipment and skills. This technique could be used to fit 35mm cap to 40mm clamps in just about

any unit.

What do you do when you need a high quality 12,000uf capacitor that is 40mm x 100mm and can't find one?

Well, if you can find a 40mm diameter that is anywhere form 60-100mm you can make that work, but the 40mm diameter is

something you just got to have. You can change all the mounting hardware, and drill new mounting holes... sometimes (but I

hate drilling new holes into a vintage piece of equipment). Most often, there are limiting factors, such as space, specialized

clamps and hardware, or PCB layout that prohibits the use of anything except the proper diameter cap. This is the case with

the KA-9100...

The mounting clamps are a unique double capacitor bracket. Further, the rectifier board mounting positions are dependent on

the capacitors because the boards hang from the base of the capacitors. The clamp holds the whole thing in position. The

position of the boards are critical because the tolerances between the components and PCB hardware and the frame are

small.

You just have to have 40mm capacitors!!! I looked everywhere for 40mm x 12,000uf caps... nothing!!!

40mm is an old standard and not many caps are available in this diameter today. These days, you find 35mm as a common

standard size. So, the best I could find was 35mm x 70mm.

This next section describes what I did to make these work with the original clamps and hardware. It worked quite well, but

requires some specialized equipment and skills. This technique could be used to fit 35mm cap to 40mm clamps in just about

any unit.

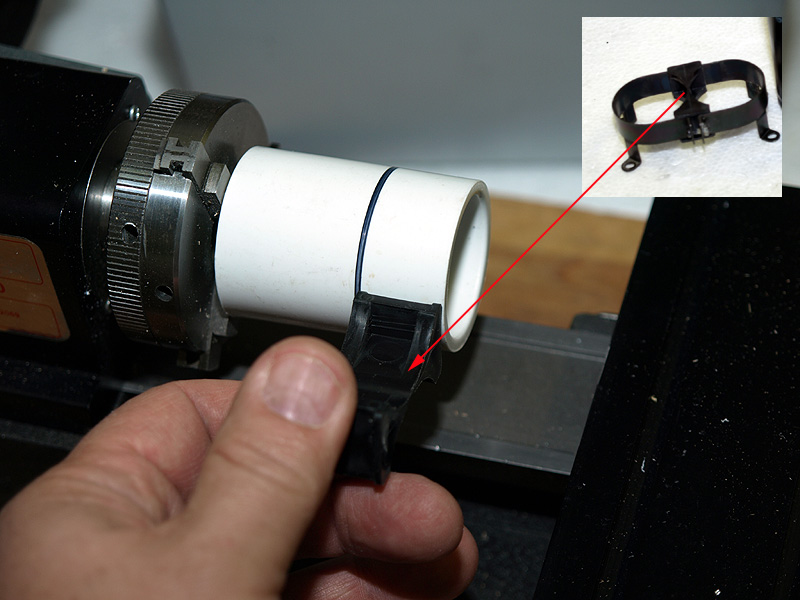

Start with a 1 inch PVC pipe joint. Guess what the outside dimater of this1 inch pipe joint is?... yup, 40mm.

Chuck it into a lathe, and mark the width of the clamp for reference.

Chuck it into a lathe, and mark the width of the clamp for reference.

Next, use a mini gouge and ream the inside of the pipe joint out by about 1/16 of an inch, all the way back to the reference

line. You know it is the right diameter when the 35mm cap will slip easily into the joint.

line. You know it is the right diameter when the 35mm cap will slip easily into the joint.