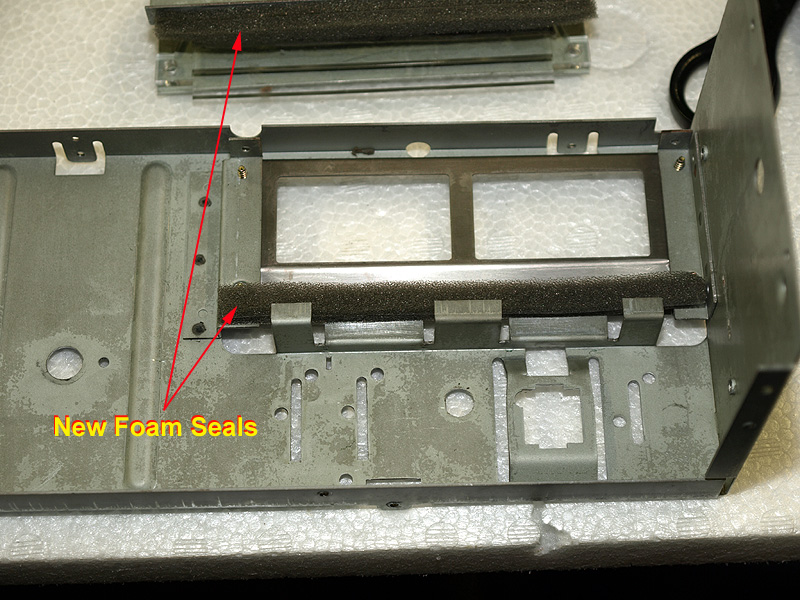

After cleaning, the front sub-panel gets a new foam seal for the meter and meter lights.

This face plate is in pristine condition. However, the switch trim pieces had some spots of oxidation (tin/nickel alloy platting). I

removed all the trim pieces including the round button trim and glass/glass trim still shown in the picture. This picture was

taken while work was still in progress. It is a time consuming job to remove the trim, as they are glued in. The glue must be

softened with solvent. The solvent must be applied sparingly 4 or 5 times with an artist brush around one or two of the pieces

at a time from the back side. The solvent must not be allowed to run onto the face front as it can remove the black from the

lettering. I used lacquer thinner. Once the glue has softened, the trim piece can be push from the face. The excess glue

should be cleaned up so that the piece will re-seat firmly to the face.

I tumbled the trim pieces in a drum tumbler with cob, fortified with a mild metal polish for 5 hours. This shined up the pieces

nicely. However, the oxidation of the tin in the plating left some discoloration. It is not noticeable unless you are looking for it.

The trim pieces are plated plastic so a plastic safe adhesive needed to be used when re-gluing. I used 3M Rubber

and Vinyl #80. This is a contact type of adhesive and worked very well.

removed all the trim pieces including the round button trim and glass/glass trim still shown in the picture. This picture was

taken while work was still in progress. It is a time consuming job to remove the trim, as they are glued in. The glue must be

softened with solvent. The solvent must be applied sparingly 4 or 5 times with an artist brush around one or two of the pieces

at a time from the back side. The solvent must not be allowed to run onto the face front as it can remove the black from the

lettering. I used lacquer thinner. Once the glue has softened, the trim piece can be push from the face. The excess glue

should be cleaned up so that the piece will re-seat firmly to the face.

I tumbled the trim pieces in a drum tumbler with cob, fortified with a mild metal polish for 5 hours. This shined up the pieces

nicely. However, the oxidation of the tin in the plating left some discoloration. It is not noticeable unless you are looking for it.

The trim pieces are plated plastic so a plastic safe adhesive needed to be used when re-gluing. I used 3M Rubber

and Vinyl #80. This is a contact type of adhesive and worked very well.