It is particularly sad when a vintage item, that has been out of production for many years, is damaged or destroyed in shipping. Once these things are gone, they are gone forever. Vintage audio gear is no exception. Some of the finest audio equipment ever produced came from the 60's and 70's. So why would we pack these as we would a box of shoes?

Far too many people do not take packing seriously enough. Either they are afraid to spend the money for proper material, or they just do not understand the abuse most packages get while in the care of shippers. Packages over 25lb are particularly prone to damage for several reasons.

- Inertia is the property of an object to resist changes in velocity unless acted upon by an outside force. The more mass (weight) an object has, the more it resists change.

-

kinetic energy is the energy of motion. An object which has motion has kinetic energy

This energy is directly proportional to mass and velocity as described in:

KE = 1/2 x mass x velocity2

Since velocities experienced in the handling of packages are fairly constant (limited to the acceleration of gravity, and the strength it takes to toss a large package) , it is clear to see that mass will play the significant roll in the stresses of shipping.

A 5Lb box of shoes dropped to the ground has nowhere near the same energy and inertia as a 25lb receiver dropped from a similar height. The boxes maybe very similar in size and will accelerate to the floor and hit at very similar speeds.

For example... the 5Lb box dropped from a hight of 4 feet produces about 20ft. lb. of energy while a 25LB box produces a whopping 99.5ft. lb. A 45 pound receiver will generate a crushing 179ft. lb. of force. Ever seen a box with 175Lb in it hold up? Not without special reinforcing.

A heavy package in motion quickly surpasses the ability of standard boxes, packing peanuts, and bubble wrap to contain and absorb the energy that will be released when the object is brought to a sudden stop. The corner or edge of a heavy object will pierce any number of layers of bubble wrap and penetrate packing peanuts as if they were not there. The box will offer little protection (it is just a container). All the energy will trasfer to the point of impact.

I have seen all kinds of things used as packing material. Wadded newspapper seems popular. Disposable paper bed coverings (like they use in hospitals).

I once got an amplifier wrapped in a down blanket. The amp was destroyed in shipping and I parted it out... I still have the blanket though.

I have received some units just dropped in a box!!! nothing else. I don't have to tell you what shape those were in when they arrived.

Let's look at the financials of poor packing.

It is cheaper to use standard material such as bubble wrap, peanuts,and the single walled boxes you get at the shippers, and this material is fine for lighter objects, but it has it limitations.

Single walled box + roll of bubble wrap + some peanuts = about $12.00

Now let's say it gets damaged in shipping. You will have an unhappy customer which will certainly cost you future business (-$$$$). Let say you take the product back and send a refund as an attempt to appease the customer (-$$$). Your customer is still not happy until you refund shipping also (-$$$). Now you have a broken product worth substantially less (-$$$). To move the broken product you will have more sales cost (-$$).

Let's look at the cost of proper packing.

Double walled box + foam padding + visqueen = about $25.00

So now, is it really cheaper? It does not take too many "broken in shipment" packages to take the profit out of your business for a long time.

You can pack properly for less if you buy quantity, and shop at outlets. I find foam padding at the local fabric outlet for $5-$7 for 4x7 sheets (this is enough to pack three shipments). If you can find a manufacture of mattresses or furniture, they may let you have the foam cuttings for free. Movers are a good source for used doubled walled boxes.

| Packing Heavy Items |

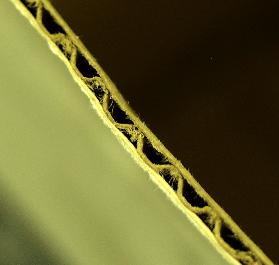

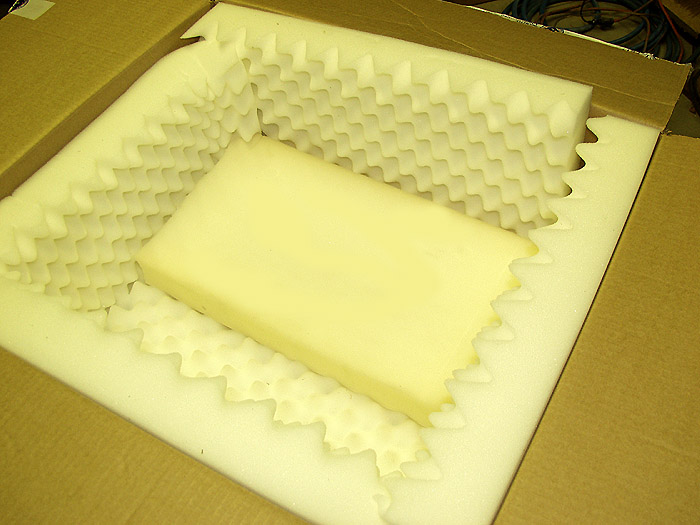

should have a minimum of 4 inches between the object and that box walls.

of foam on the bottom will allow extra "give" to both top and bottom of box. Boxes are dropped to the ground

on a regular basis.

visqueen which is also known as "painter's

plastic". It is cheap and will work well to protect

the object from abrasion and dust.

Yes... foam can be abrasive to a fine finsh.

Vibration and repetitive motion can affect the

"sheen" of a finished surface.

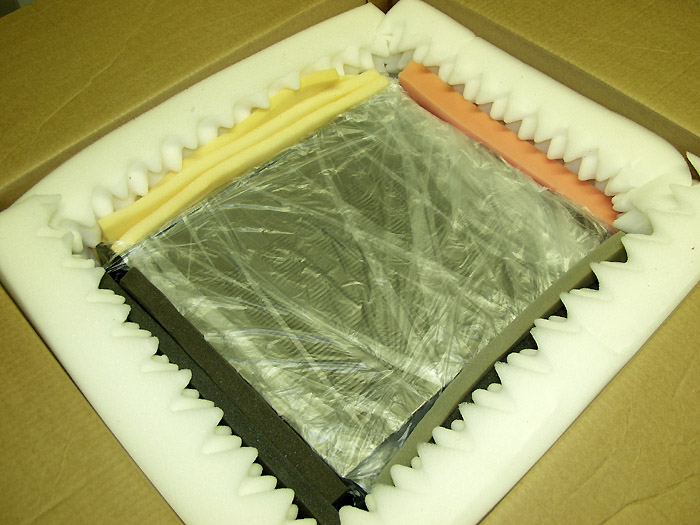

don't want the item banging around in the box. So add padding as seen below. The packing should be snug...

not tight, not loose.

in a dispenser.

Tape the box along all the seams first

(blues arrow). Do this on top and bottom

of box. Overlap two more strips of tape

on each side of the seam strip (red

arrows). These should overlap slightly in

the center by a small amount, directly

over the seam.. This gives you triple

layers of tape directly over the seam.

Label the "Top" with a marker.

This is fairly bullet proof. When you are dealing with vintage gear such as amplifiers and receivers proper packing is essential. You can't call up Pioneer and ask them to send you a new face plate for your SX-1050. Once it's damaged, it's a costly endeavor to repair. You're left waiting and watching to find a unit that can be cannibalized for parts.