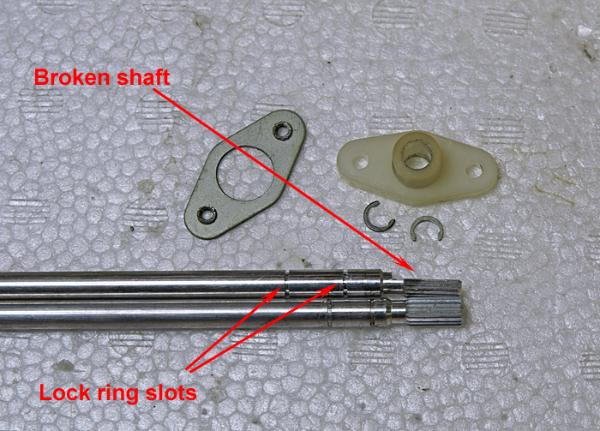

Now we need to fix the broken selector shaft.

I used a shaft from a KA-9100 as a base to create a

new selector shaft. What we need to do, is to cut

the lock ring slots in the correct location to give

the correct forward length and the correct depth

for the bushing.

I used a shaft from a KA-9100 as a base to create a

new selector shaft. What we need to do, is to cut

the lock ring slots in the correct location to give

the correct forward length and the correct depth

for the bushing.

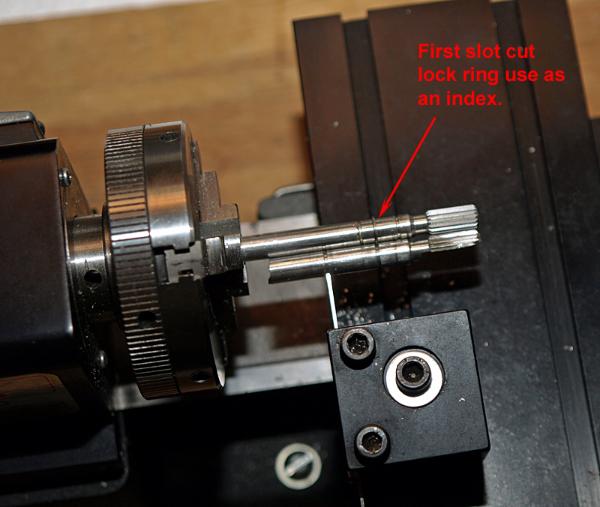

I cut the first lock ring slot and installed the lock

ring. This now gives us an index to locate the

second slot position. A short section of the

broken shaft end is located over the lock ring.

The lathe is then adjusted to align with the rear

lock ring slot. The short section shaft is then

removed and the cutoff tool is then moved into

position to make the cut.

ring. This now gives us an index to locate the

second slot position. A short section of the

broken shaft end is located over the lock ring.

The lathe is then adjusted to align with the rear

lock ring slot. The short section shaft is then

removed and the cutoff tool is then moved into

position to make the cut.

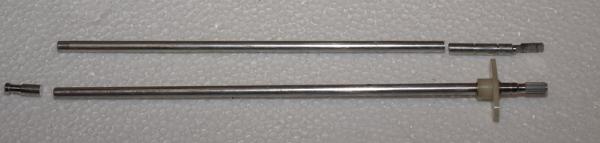

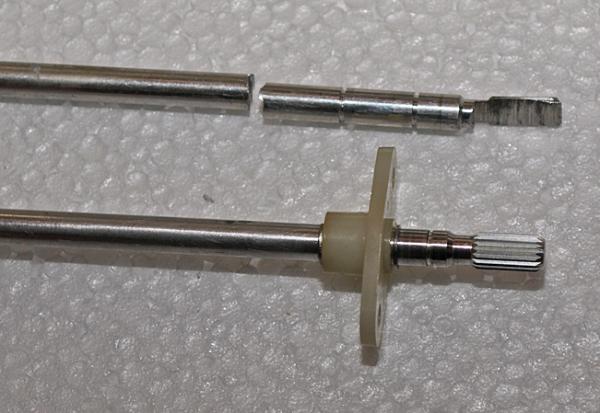

Here we have it...

The shaft is cut to length and a flat surface is

notched into the end for the set screw.

notched into the end for the set screw.