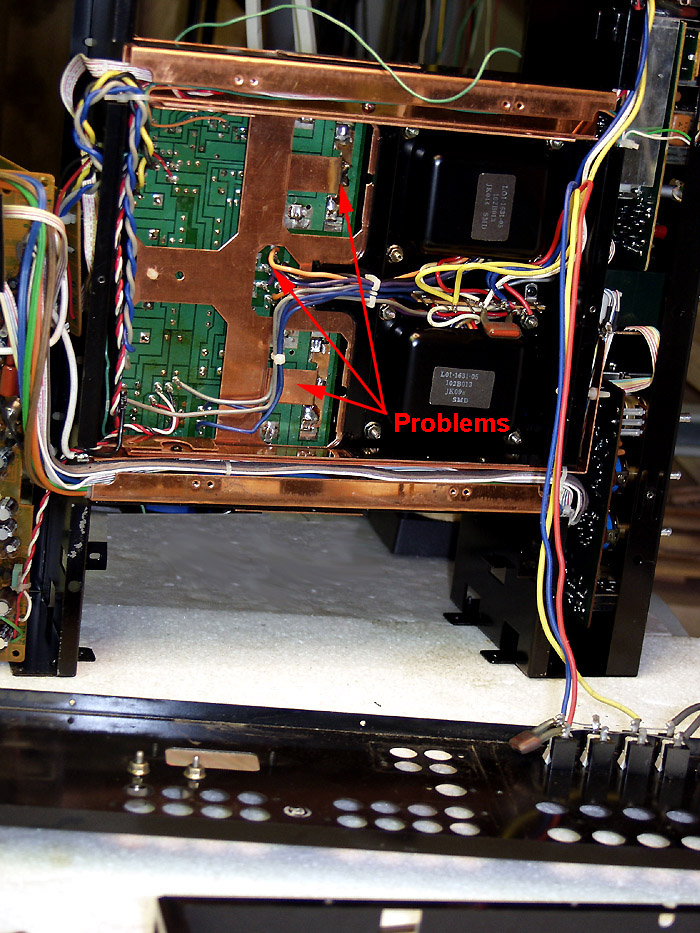

This is the first KA-907 I have worked on. While stripping this down I found a few road blocks.

First, the large supply capacitors are soldered to the power supply board, which is soldered to

the copper chassis. The solder joint is massive.

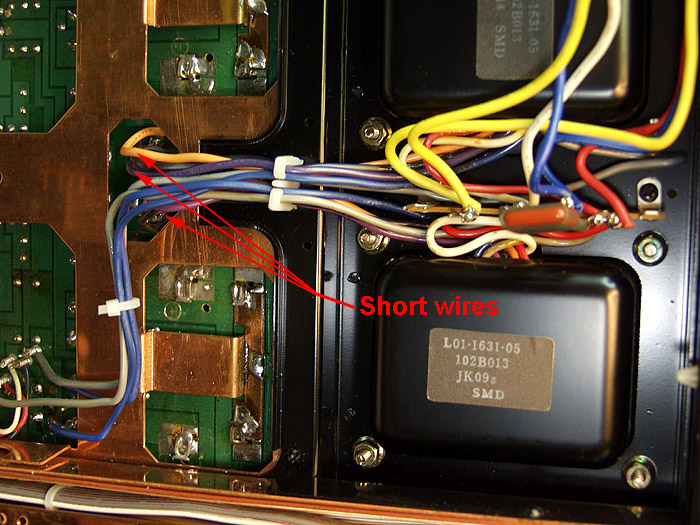

Second, the power supply leads to the main power supply board have very little "extra" length.

First, the large supply capacitors are soldered to the power supply board, which is soldered to

the copper chassis. The solder joint is massive.

Second, the power supply leads to the main power supply board have very little "extra" length.

The solder joint runs the full

length of the copper ground

strap. You can't tell from the

picture, but under the copper

strap is a solid bead of solder,

which runs from end to end. I

did not want to attempt to

remove that much solder. The

copper frame will act as a big

heat sink, which will increase

greatly the amount of heat

needed to loosen the solder.

There is a big risk of damaging

the board doing this.

length of the copper ground

strap. You can't tell from the

picture, but under the copper

strap is a solid bead of solder,

which runs from end to end. I

did not want to attempt to

remove that much solder. The

copper frame will act as a big

heat sink, which will increase

greatly the amount of heat

needed to loosen the solder.

There is a big risk of damaging

the board doing this.

There was not enough free wire on the transformer leads to allow for rewapping the

wires. Each time a wire is unwarpped from a post, you lose the length of wire which

was wrapped around the post. This is generally about 1.5 - 2 inches. You will need at

least this much "free" wire to strip and rewrap. Kenwood usually leave generous

amounts of wire in their units for this. hummmm... someone been in this unit before? or

is this a cost cutting thing?

wires. Each time a wire is unwarpped from a post, you lose the length of wire which

was wrapped around the post. This is generally about 1.5 - 2 inches. You will need at

least this much "free" wire to strip and rewrap. Kenwood usually leave generous

amounts of wire in their units for this. hummmm... someone been in this unit before? or

is this a cost cutting thing?

I decided that a complete strip-down was too risky. The risk of causing unrepairable

damage was too high. I decided to restore the amp in sections. This included new

caps, washing all surfaces, grooming the components on the boards, and then voltage

checks after assembly.

1. First the center section of the amp (power supply boards, transformers, and center

section of the chassis.

2. Frontend (tone controls and front chassis section)

3. Backend (inputs, back panel, back side of chassis)

4. Output sections (output tansistors, heat sinks)

5. Face plate, cover, bottom plate, knobs

damage was too high. I decided to restore the amp in sections. This included new

caps, washing all surfaces, grooming the components on the boards, and then voltage

checks after assembly.

1. First the center section of the amp (power supply boards, transformers, and center

section of the chassis.

2. Frontend (tone controls and front chassis section)

3. Backend (inputs, back panel, back side of chassis)

4. Output sections (output tansistors, heat sinks)

5. Face plate, cover, bottom plate, knobs